Quick Menu

- RISING SUN 3D - ON DEMAND 3D PRINTING

- Ak Interactive

- All Game Terrain

- Ammo by MIG

- Army Painter

- Backpacks and Carrycases

- Bifrost Airbrush Paints

- Coming Soon!

- Connectors

- Chargers

- Gift Cards

- Laser Cutter, Engravers and CNC

- New Items

- Painting Brushes and Tools

- Sale!

- Services

-

- SMS - Premium Acrylic Lacquer Series

- SMS - Pearl Acrylic Lacquer Series

- SMS - Auto Colour

- SMS - Brush Series

- SMS - Cements & Adhesives

- SMS - Colour Sets

- SMS - Colour Shift Acrylic Lacquer Series

- SMS - Crystal Acrylic Lacquer Series

- SMS - DragonAir Airbrushes

- SMS - Effects Acrylic Lacquer Series

- SMS - HyperChrome Series

- SMS - Infinite Colour - Water Based

- SMS - Masking Series

- SMS - Metallic Acrylic Lacquer Series

- SMS - Precision Tools Series

- SMS - Primer Series

- SMS - Thinners, Additives and Paint Remover

- SMS - Weathering Series

- SMS - Wildlife Colours

- STEM

- Trading Card Games

- The Used

- X Class Gear

- Blogs

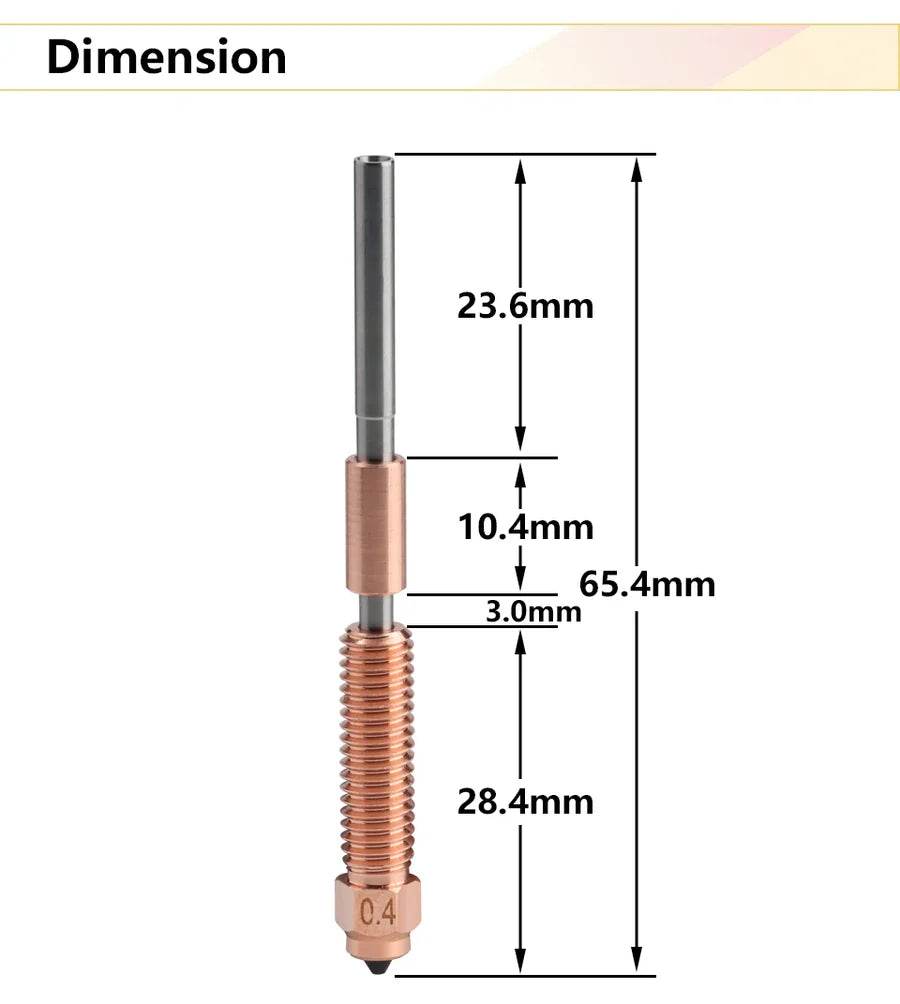

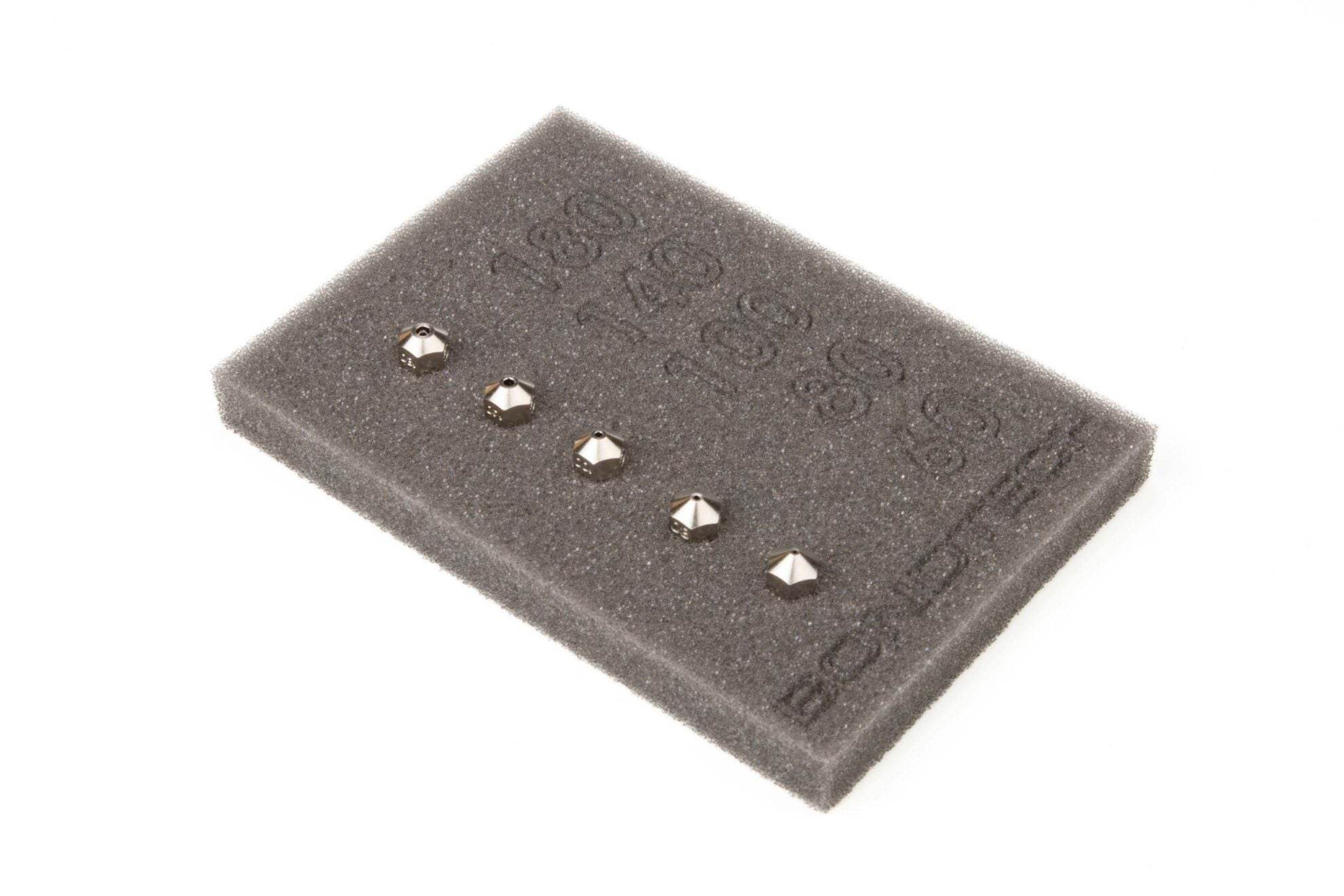

3D Printer Nozzles

58 products

Showing 1 - 48 of 58 products

3D Printer Nozzles – Precision Nozzles for Every Printing Need

Achieve better print quality, faster speeds, and superior reliability with premium 3D printer nozzles from Rising Sun FPV.

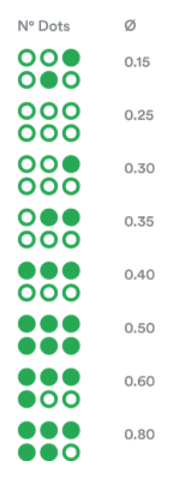

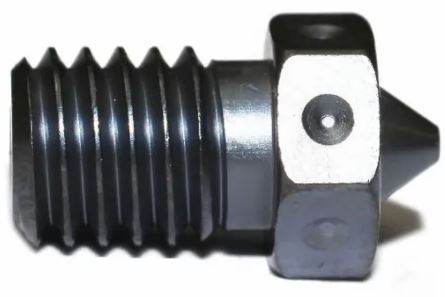

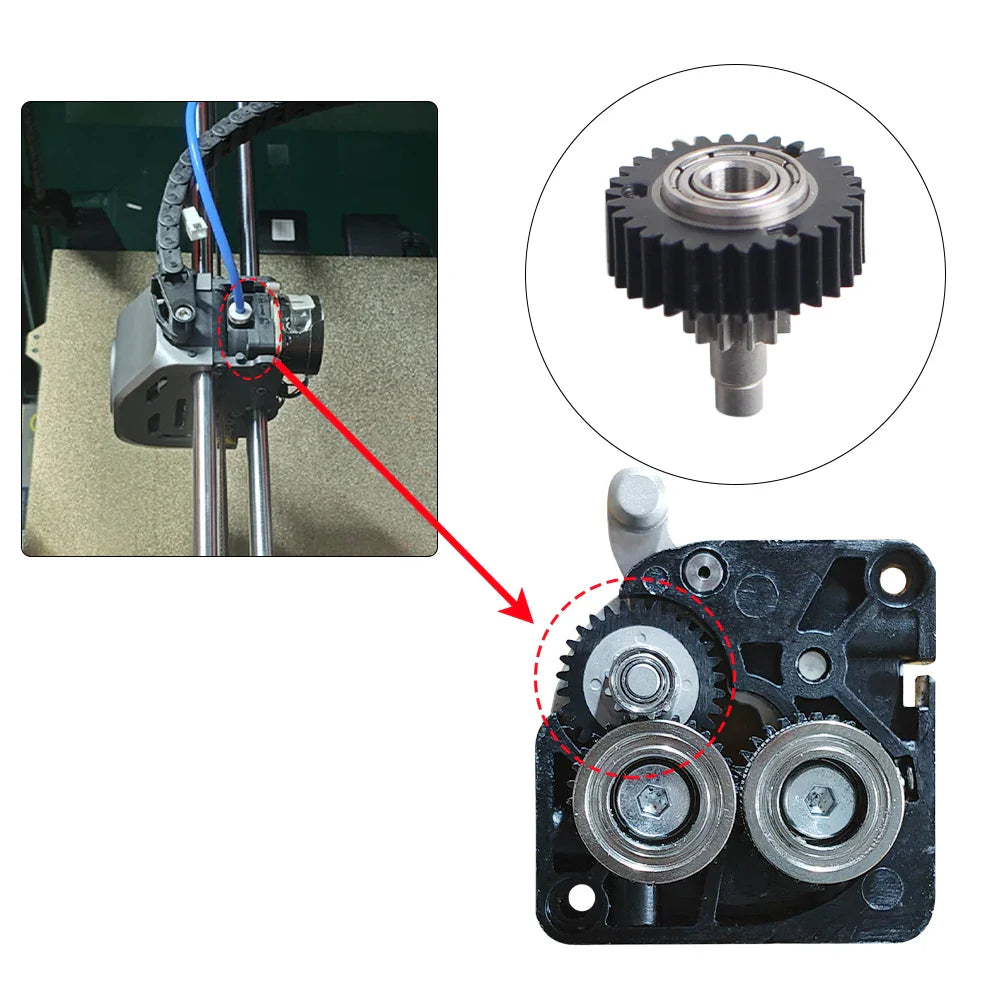

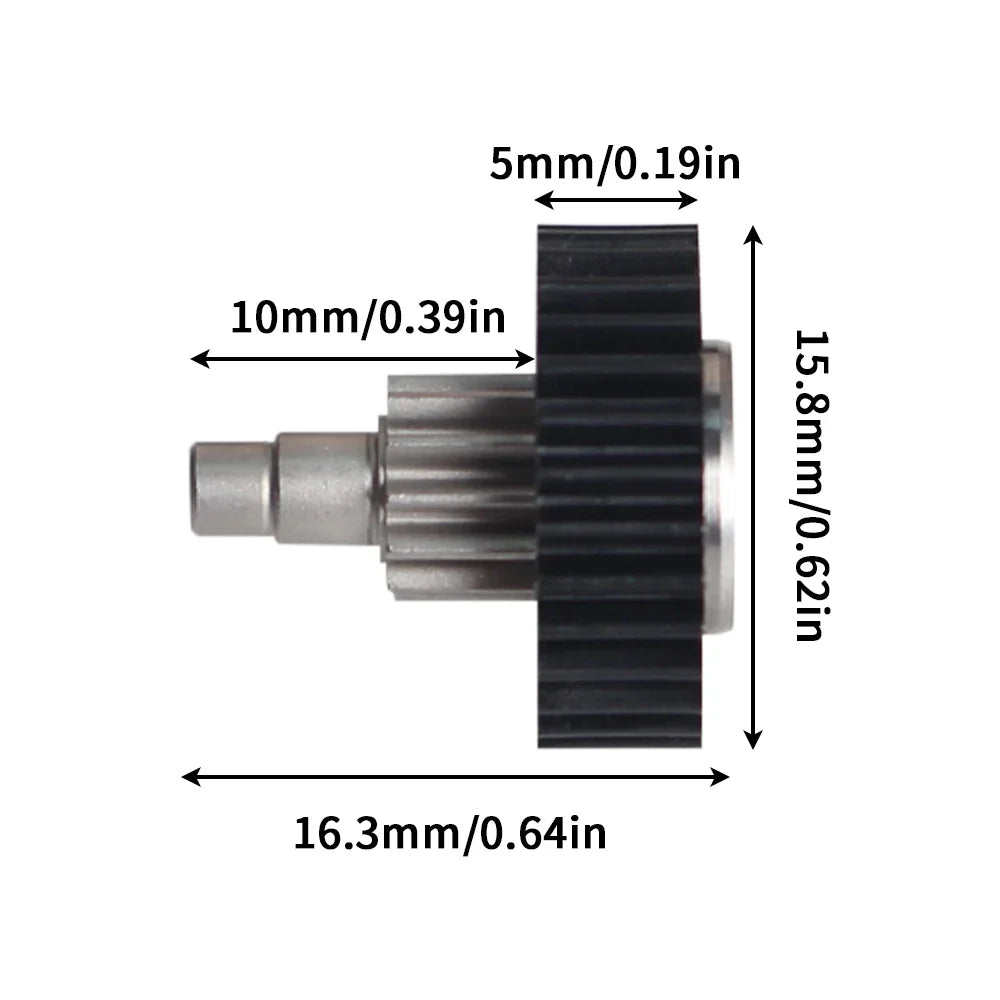

Our 3D Printer Nozzles collection features a wide selection of high-performance nozzles, including brass, hardened steel, ruby-tipped, and specialty nozzles — carefully chosen to meet the demands of hobbyists, professionals, and industrial users alike.

Whether you're printing with basic PLA, abrasive carbon fiber composites, flexible TPU, or high-temperature engineering materials, we have the right nozzle for your printer and your project.

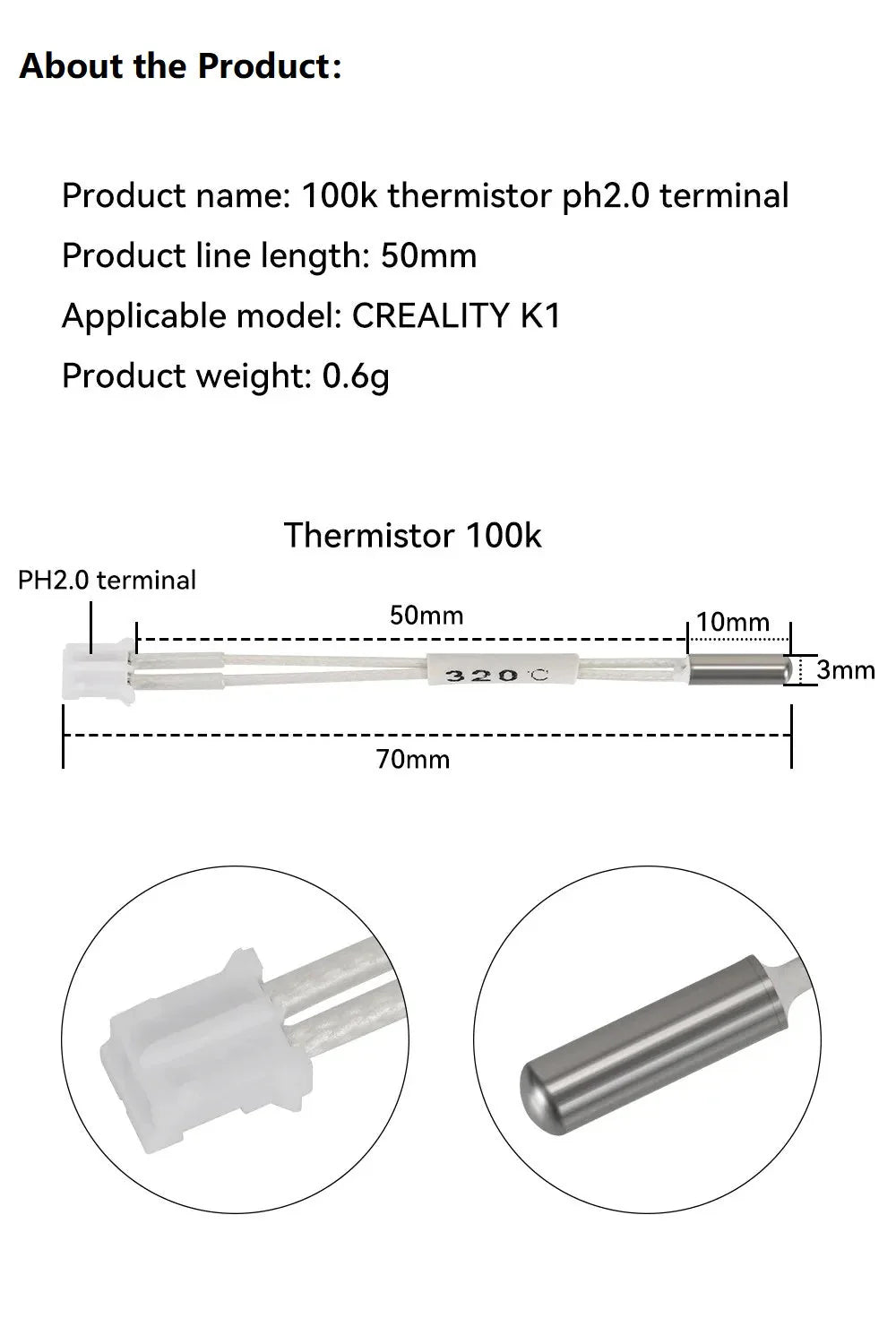

We stock genuine nozzles compatible with popular brands like Prusa, Creality, Bambu Lab, and more — ensuring precision extrusion, long service life, and easy installation.

Print stronger, faster, and cleaner — shop Australia's best 3D printer nozzles at Rising Sun FPV today.