PLA with Improved Sandability

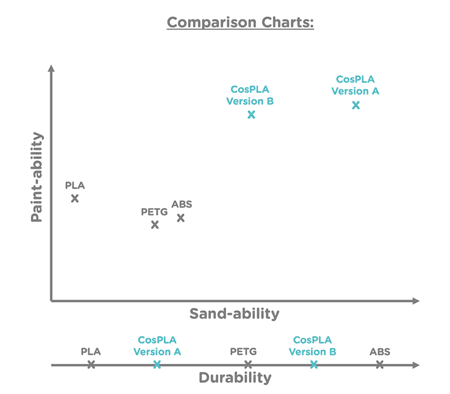

Regular PLA filaments can be very difficult to sand due to their hardness. To speed up your workflow, Polymaker CosPLA Version B has been developed to offer improved sandability compared to regular PLA materials. The combination of durability, sandability and ease of painting make CosPLA version B the perfect choice for your next cosplay 3D printing project.

Compatibility in mind & Jam-Free™ Technology

Polymaker CosPLA Version B is compatible with a wide range of 3D printers and works well with many common printing surfaces and a 30 - 60°C heated bed. Polymaker CosPLA Version B is manufactured with Polymakers Jam-Free™ technology which improves the heat stability of the filament with softening temperatures over 140°C and leads to excellent printing quality with zero risk of nozzle jams caused by heat creep [1]. Manufactured with Polymakers industry leading compounding and extrusion systems, Polymaker CosPLA Version B filament is made with the highest quality ingredients and formulated to deliver a reliable 3D printing filament for cosplay and prop applications.

[1] Heat creep is the the process of heat spreading irregularly throughout the hot end, one common example is with all metal hot end designs. Once heat creeps towards the cold end, the PLA filament softens prematurely in the cold end and expands resulting in a jam. Polymakers Jam-Free™ technology increases the heat resistance of the filament itself (not the printed part) to 140˚C which prevents the filament from prematurely softening in the cold end and can still melt rapidly once entering the heating zone.

To learn more about Polymaker CosPLA Version B, click the "Suggested Applications", "Specifications & FAQ" and "Polymaker / Quality" tabs.

Printing Settings

| Nozzle Temperature |

190°C - 230°C |

| Build Plate Temperature |

25°C - 60°C |

| Build Surface Material |

Works well with most build surfaces i.e Glass, Blue Tape, BuildTak® etc |

| Build Surface Treatment |

Can apply Magigoo Original or PVA glue to the build surface to improve adhesion. |

| Cooling Fan |

ON |

| Printing Speed |

30 mm/s - 60 mm/s |

| Retraction |

The ideal retraction settings vary from printer to printer, the following settings may help.

Direct Drive: Retraction distance of 1mm with retraction speed of 30mm/s.

Bowden: Retraction distance of 3mm with retraction speed of 60mm/s

|

| Recommended Support Material |

Single Extrusion:

Self Support

Dual Extrusion:

PolyDissolve™ S1 (Dissolve in tap water)

PolySupport™ (Easy break-away support material)

|

Based on 0.4 mm nozzle. Printing conditions may vary with different printers, higher speeds / flow rates and nozzle diameters.

For other tips printing Polymaker CosPLA contact us!

Specification

| Net Weight |

1kg |

| Material Type |

Specialised Cosplay PLA |

| Density |

|

| Colour |

Hex Code: #

|

Compatibility

Polymaker CosPLA PLA has been engineered with compatibility in mind to print excellently on a wide range of 3D printers. The Jam-Free™ technology implemented into Polymaker CosPLA can improve compatibility with all metal hot end designs that suffer from heat creep.

Of course with thousands of unique 3d printer models on the market, we can't guarantee each filament type will work with every 3D printer.

STORAGE & DRYING

Before packaging, Polymaker CosPLA is dried to ensure the best printing quality and filaments are vacuum sealed to protect the filament from moisture. When not in use Polymaker CosPLA should be stored away from sunlight in the packaged resealable bag.

Like other PLA filaments, Polymaker CosPLA is susceptible to absorbing moisture from the air which can subsequently effect the quality and mechanical properties of the final prints. We recommend storing Polymaker CosPLA in the PolyBox™ or a dry cabinet during printing to prevent moisture absorption which will lower the quality of the print. The PolyBox™ keeps the filament at dry conditions (relative humidity of 15% or less).

If you hear popping sounds and notice that the surface quality of your print is uneven or the colour is not consistent, this is a likely indicator that the filament has absorbed too much moisture. Spools of Polymaker CosPLA can be dried in a preheated convection oven at 55˚C for up to 6 hours. Results may vary depending on the accuracy of your oven so please be conservative. For more information about filament drying please read our user guide.

FAQ

Q: Does Jam-Free™ technology prevent all filament jamming?

A: Jam-Free™ technology is designed to prevent jamming caused by heat creep. There are many reasons why a material may jam, such as a partially blocked nozzle, printing with the wrong extruder temperature or incorrect nozzle height; Polymaker's Jam-Free™ technology won't prevent jamming in these cases.

Q: Is Polymaker CosPLA Version B a PLA+ material?

A: Yes, Polymaker CosPLA Version B could be defined as a PLA+ material as it delivers significantly improved impact strength compared to regular PLA. Both CosPLA Version B and PolyMax™ PLA are a popular choice among prop makers.

Q: Can PLA be printed at large scales without warping?

A: One of the benefits of PLA is the ability to print large parts with excellent dimensional stability and we have many customers printing large full-size printing projects in Polymaker CosPLA. When printing large parts it is recommended to print PLA with a heated bed and to partially enclose the printer to protect the print from drafts and sudden temperature changes. Please note that while PLA materials don't warp in most situations, printing with poor first layer adhesion can cause any material to warp and printing or the heated bed too hot can cause PLA filament to undergo a crystallization process which generates internal stresses and warping.

Q: What support materials can I use with this product?

A: If your 3D printer supports multi-material 3D printing, Polymaker CosPLA is compatible with Polymaker’s PolySupport™ and PolyDissolve™ S1 filament. PolySupport™ is a breakaway support material which can be easily peeled away and PolyDissolve™ S1 is a water dissolvable support material, ideal for complex geometries.

Q: Should I rewind this filament if I want to use it with a different spool?

A: We strongly advise against tampering with the product by rewinding. See our article for full details about the risks. All Polymaker filaments are wound with tension but without strain. Rewinding completely rearranges the curvature of the winding and this strain over time can cause most plastics to catastrophically break. If for some reason your printer is locked into fitting less than standard sized spools, there may be safe printable adaptors or external mounting solutions available.

Don't know where to start? Or which filament will suit your application? We have a broad range of support options including telephone support. Contact us today!