PVA based water dissolvable support for PLA, TPU, PVB and Nylon filaments.

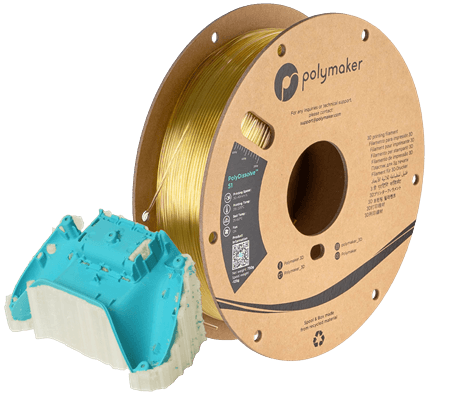

PolyDissolve™ S1 is a water dissolvable support for PLA, TPU, PVB and Nylon based filaments from Polymakers portfolio. It is specifically engineered to have a perfect interface with these materials while also displaying good solubility.

We recommend that this material be used with the PolyBox™ to keep it at dry conditions (relative humidity of 15% or less) at all times to maintain the best printing results.

Features

Complex Geometry - PolyDissolve™ S1 is a preferable solution when printing complex geometries, overhangs, internal cavities and complicated structures. It liberates you from support removal problems, and enables greater design freedom.

Wide material support - PolyDissolve™ S1 is engineered to have a good adhesion and perfect interface with a variety of supported materials from Polymaker including Nylon, PLA, TPU and PVB.

Water Soluble - Optimised to dissolve in water, supports printed in PolyDissolve™ S1 will dissolve in tap water. Safe and easily accessible!

Improved surface quality - Greatly improve the surface quality where supports interface with your prints when using PolyDissolve™ S1.

Quality Control - Polymakers leading quality control process and rigorous in-house testing, ensure reliable printing and consistency across spools and batches.

To learn more about PolyDissolve™ S1, click the "Why people are using it", "Quality & Technology" and "Settings & Specifications" tabs.

Bones 3D printed in PolyLite™ PLA with PolyDissolve™ S1.

When printing some materials or parts with complex geometry it can be really difficult and time consuming to remove supports. Sometimes special tools are required to break supports away from the model and in many cases prints can fail due to support related issues.

Manifold 3D printed in PolyMide™ CoPA with PolyDissolve™ S1 supports.

Specifically engineered as a soluble support material for a wide range of plastics, PolyDissolve™ S1 can be dissolved in tap water, simplifying and in many ways automating the tricky part of the support removal process. With water soluble supports users can print more complex and delicate geometry and remove supports safely without risk of breaking the part.

Vessels 3D printed in PolyFlex™ TPU95 with PolyDissolve™ S1 supports.

PolyDissolve™ S1 softens and dissolves in ordinary tap water. The dissolving process can be sped up through regular replacement, agitation or using heated water.

PolyCast™ 3D print with PolyDissolve™ S1 supports.

PolyDissolve™ S1 has become the go to choice for many users due to its compatibility with a wide range of materials. Traditionally removing supports from materials like Nylon and TPU can be harder but with PolyDissolve™ S1 it is easy. Engineered to perfectly bond with Polymakers PLA, TPU, PVB and Nylon based filaments, with PolyDissolve™ S1 you don't need to invest in a unique support material for each different material type.

|

Filament |

| Diameter |

1.75mm |

| Spool Weight |

750g |

All Polymaker products are formulated by Polymakers experienced R&D team to provide new optimised and innovative material solutions for the industry. Whether it be improving printing reliability & experience (Warp-Free™, Jam-Free™) to maximising material performance and functionality (Layer-Free™, Nano reinforcement). Polymakers patented technologies and expansive portfolio have continued to provide empowering solutions to customers internationally, from Automotive manufacturers and Construction companies right down to the entrepreneur and household maker.

Industry Leading Quality Control

PolyDissolve™ S1 like all other Polymaker materials is manufactured using state-of-the-art polymer processing technologies and equipment. Polymakers rigorous quality control process ensures industrial standards of reliability for a consistent customer experience.

Tolerance: Polymakers custom developed extrusion, control and monitoring solutions ensure filament tolerance (typical tolerance ± 0.02mm) and roundness meet Polymakers strict quality standards.

Reliable Mechanical, Colouring & Printing Properties: Every batch of filament products are tested to ensure all quality specs (melt flow, softening point, mechanical, diameter, round-ness) are met.

Drying & Vacuum Sealing: Before packaging, all Polymaker filaments are dried to a moisture level of < 0.1% to ensure the best printing quality and are vacuum sealed to protect the filament from moisture. All vacuum packaged products are left for 24 hours before boxing to ensure they are leak-free.

Packaging

Transparent Spool: PolyDissolve™ S1 is carefully wound on Polymakers 750g transparent spools. With the transparent spool and the weight gauge, it is easy to see exactly how much filament is left for your next printing project.

Resealable Bag: PolyDissolve™ S1 is packaged in an aluminium foil resealable bag to ensure your filament is moisture free. Like all PVA based materials, PolyDissolve™ S1 is hygroscopic so we highly recommend keeping this bag for filament storage.

Printing Settings

| Nozzle Temperature |

215˚C – 225˚C |

| Build Surface material |

Glass, blue tape, BuildTak® |

| Build surface treatment |

Can apply PVA glue to the build surface |

| Build plate temperature |

25˚C – 60˚C |

| Cooling fan |

ON |

| Printing speed |

20mm/s – 40mm/s |

| Works best with |

Supports the model very well

- PLA based materials (such as PolyLite™ PLA, PolyMax™ PLA, PolyWood™)

- TPU based materials (such as PolyFlex™ TPU95)

- PVB based materials (such as PolyCast™ and PolySmooth™)

- Nylon based materials (such as PolyMide™ CoPA, PolyMide™ PA6-CF and PolyMide™ PA6-GF)

Generally supports the model depending on its geometry

- PETG based materials (such as PolyLite™ PETG and PolyMax™ PETG)

|

Storage & Drying

Before packaging, PolyDissolve™ S1 is dried to ensure the best printing quality and filaments are vacuum sealed to protect the filament from moisture. When not in use PolyDissolve™ S1 should be stored away from sunlight in the packaged resealable bag.

PVA is hygroscopic so it is highly recommended to store PolyDissolve™ S1 in the PolyBox™ or dry cabinet during printing to prevent moisture absorption which will lower the quality of the print. The PolyBox™ keeps the filament at dry conditions (relative humidity of 15% or less).

If you hear popping sounds and notice that the surface quality of your print is uneven or the color is not consistent, this is a likely indicator that the filament has absorbed too much moisture. Spools of PolyDissolve™ S1 can be dried in a preheated convection oven at 80˚C for up to 12 hours. Results may vary depending on the accuracy of your oven so please be conservative. For more information about filament drying please read our user guide.

Specification

| Net Weight |

750g |

| Diameter |

1.75 mm |

| Density |

1.37 (g/cm3 at 21.5˚C) |

| Technologies |

N/A |

Material CompatIbilities

PLA based material from Polymaker’s portfolio + +

PETG based material from Polymaker’s portfolio +

ABS based material from Polymaker’s portfolio – –

PC based material from Polymaker’s portfolio – –

PVB based material from Polymaker’s portfolio + +

TPU based material from Polymaker’s portfolio + +

Nylon based material from Polymaker’s portfolio + +

+ + supports the model very well

+ generally support the model depending on its geometry

– generally doesn’t support the model depending on its geometry

– – do not support the model

We have full SDS and technical data sheets for PolyDissolve™ S1 and all other Polymaker products. Contact us to enquire!

Compatibility

PolyDissolve™ S1 has been engineered with compatibility in mind to interface perfectly with Polymaker PLA, PVB, TPU and Nylon filaments and to print excellently on a wide range of professional 3D printers.

To print multi-material soluble supports, a dual extrusion 3D printer capable of printing both the modelling and support material at different temperatures is required. (i.e left nozzle at 200˚C and right nozzle at 215˚C).

Of course with thousands of unique 3d printer models on the market, we can't guarantee each filament type will work with every 3D printer.

FAQ

Q: How do I dissolve my supports?

A: PolyDissolve™ S1 can be dissolved in regular tap water. The dissolving time will depend on many factors including the volume of support material. Partially removing any large support structures before submersion can significantly increase speed up the process for large models. Submerge the remaining model in regular tap water to dissolve away the rest of the support. This process can be speed up by agitating the water, using warm water (>50˚C) or regularly changing the water to reduce the concentration.

Q: How do I dispose of PolyDissolve™ S1 supports.

A: The preferred method of disposal for polyvinyl alcohol (PVA) support material is in the trash. The immersion of 3D printed objects into water containing support material will generate wastewater containing PVA. It is suggested that you contact your local Sanitary Sewer (Wastewater) Authority to obtain the proper disposal method prior to discharging to the sewer.

Q: Should I rewind this filament if I want to use it with a different spool?

A: We strongly advise against tampering with the product by rewinding. See our article for full details about the risks. All Polymaker filaments are wound with tension but without strain. Rewinding completely rearranges the curvature of the winding and this strain over time can cause most plastics to catastrophically break. If for some reason your printer is locked into fitting less than standard sized spools, there may be safe printable adaptors or external mounting solutions available.

Don't know where to start? Or which filament will suit your application? We have a broad range of support options including telephone support. Contact us today!