Same Day Dispatch

Description

Easy to print Polymaker Nylon CoPA combines high strength, toughness and heat resistance.

- Copolymer of Nylon 6 and Nylon 6,6.

- Easy-to-print with no heated bed or enclosure required.

- Excellent mechanical strength and toughness.

- Excellent dimensional stability during printing.

- High heat resistance after annealing, up to 180℃ vicat softening temperature / 110.5℃ (HDT 0.45MPa)

- Cardboard spool & packaging (made from 100% recycled cardboard)

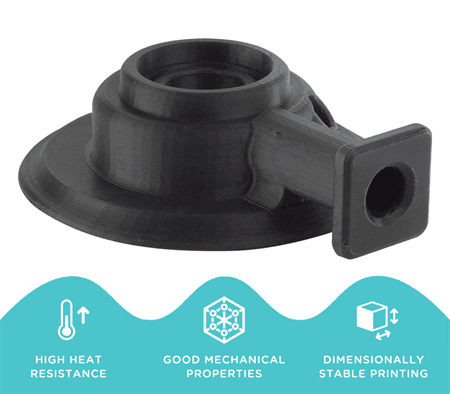

PolyMide™ is a family of Nylon/polyamide based filaments. Produced with Polymaker’s Warp-Free™ technology, PolyMide™ filaments deliver engineering properties intrinsic to Nylon and ease of printing. PolyMide™ CoPA is based on a copolymer of Nylon 6 and Nylon 6,6. The filament combines excellent strength, toughness, and heat resistance of up to 180˚C and is suited to parts in very demanding environments such as gears, engine brackets, pipe connectors or high velocity air flows.

Features

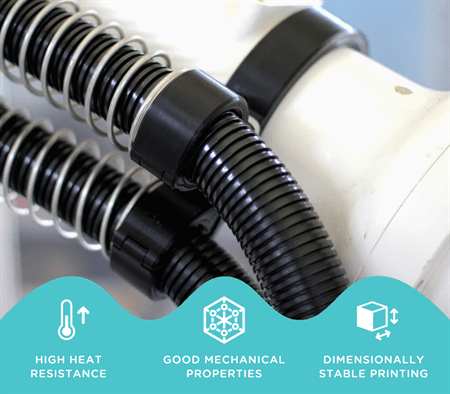

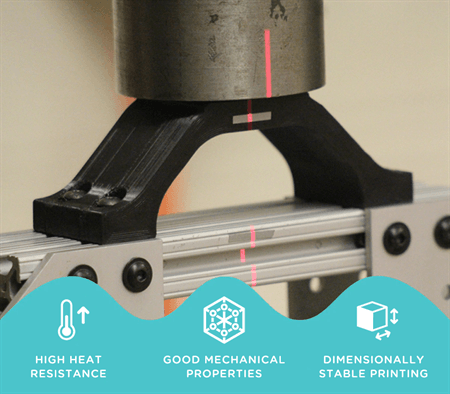

- Excellent Toughness - PolyMide™ CoPA combines outstanding mechanical strength and toughness to deliver an easy-to-use filament for engineering applications such as gears, engine brackets, pipe connectors and high velocity air flows.

- Excellent Heat Resistance - PolyMide™ CoPA can be annealed[1] after printing to produce heat resistant parts with softening temperatures up to 180 °C, PolyMide™ CoPA is one of the most heat resistant Nylon 3D printing materials on the market.

- Warp-Free™ - PolyMide™ CoPA features Polymakers Warp-Free™ technology to deliver a reliable Nylon filament with excellent dimensional stability and near-zero warpage. This is achieved by the fine control of microstructure and crystallisation behaviour of Nylon, which enables the material to fully release the internal stress before solidification. The Warp-Free™ technology in PolyMide™ CoPA is designed to work best with minimal bed temperatures.

- Improved Printability – In comparison to other Nylon filaments, PolyMide™ CoPA is extremely easy to work with. It is compatible with most filament-based 3D printers with no heated chamber or heated bed required!

- Wear Resistance - Parts printed in PolyMide™ CoPA display fantastic wear resistance.

- Uncompromised Quality - Polymakers leading quality control process and rigorous in-house testing ensure reliable printing and consistency across spools and batches.

[1] PolyMide™ CoPA displays the best mechanical and thermal properties when fully crystallized. The printed part will not reach full crystallisation during the printing process, an additional step is required: Annealing. PolyMide™ CoPA can be annealed in the oven at 80˚C for 6 hours right after the printing process.

PolyMide CoPa Comparison

Nylon plastics are hygroscopic and display different mechanical properties depending on the moisture content of the part; dry, conditioned or saturated.

Dry state represents the properties of PolyMide™ CoPA after printing and annealing, the material displays high tensile strength, stiffness (Young's modulus) and great impact resistance.

Moisture conditioned state represents the properties of PolyMide™ CoPA after annealing and conditioning the print at 70% relative humidity for 15 days. Unless coated with a moisture barrier it is assumed that all nylon parts become moisture conditioned. Moisture conditioning significantly increases the impact strength and flexibility of the Nylon 6 / 6,6.

Compare PolyMide™ CoPA with PLA, PETG and ABS

| PolyMide™ CoPA | PolyLite™ PLA | PolyLite™ PETG | PolyLite™ ABS | |

| Material | Nylon 6 / 6,6 Copolymer | PLA | PETG | ABS |

| Description | Easy to print Nylon | High quality PLA | High Quality PETG | Durable ABS |

| Nozzle Temperature Range | 250°C - 270°C | 190°C - 230°C | 230°C - 240°C | 245°C - 265°C |

| Build Plate | HBP not required 25 - 50°C |

HBP not required 25 - 60°C |

70 - 80°C | 90 - 100°C |

| Enclosure | Protects from drafts but not required. | Protects from drafts but not required. | Recommended for large parts | Recommended |

| Heated Chamber | Not recommended | Not recommended | Not recommended | Recommended for large parts |

| Dry Box with low RH% (i.e Polymaker PolyBox) |

Required |

Helpful |

Recommended |

Helpful |

| Glass Transition Temperature | 67°C | 61°C | 81°C | 101.1°C |

| Heat Deflection Temperature (0.45 MPa) |

110.5°C See HDT Curve |

59.8°C See HDT Curve |

78.4°C See HDT Curve |

99.6°C See HDT Curve |

| Vicat Softening Temperature | 180°C | 62.9°C |

84°C |

103.9°C |

| Special feature | - Easy to print with excellent dimensional stability compared to other Nylons. - Fantastic mechanical strength, toughness and flexibility. - High heat resistance and wear resistance. - Annealing required for best mechanical and thermal properties. |

- High rigidity & strength. - Easy-to-print, widest printer compatibility, best dimensional stability & lowest temperature requirements. |

- Combines good printability, mechanical properties & heat resistance with better dimensional stability than ABS, ASA & PC. |

- Balanced mechanical properties, durability & high heat resistance. - Easy to sand, paint and glue. |

| Popular with | Spare parts, manufacturing, functional prototyping. | General use | Design & functional prototyping | Design, functional prototyping & manufacturing |

Data taken from Polymakers Technical Data Sheet and is intended for reference and comparison purposes only. Due to the nature of 3D printing, data should not be used for design specifications or quality control purposes.

Nylon also known as Polyamide (PA) is one of the most popular engineering grade plastics used across a wide range of industries. There are many Nylon materials; Nylon 6 (PA6), Nylon 12 (PA12), Nylon 66 (PA66) to name a few each offering their own advantageous mechanical properties.

PolyMide™ CoPA is a copolymer specifically developed for 3D printing that combines excellent printability without compromising on the excellent toughness, tensile strength, heat, oil, grease and wear resistance properties that Nylon 6 / 6,6 offers. It has become a trusted solution for professionals and hobbyists, offering superior dimensional stability during printing when compared to other engineering materials like ABS and PC or other Nylon formulas.

- Dry applications requiring strength and toughness.

- Gears and rollers.

- Brackets, fixtures and pipe connectors.

- Demanding applications involving high heat, vibration or high velocity air flows.

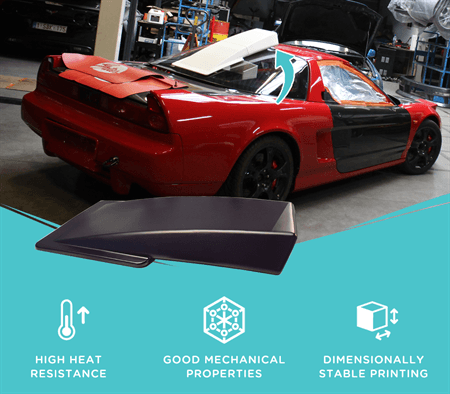

- 3D printed and post-processed air intakes and other custom automotive applications.

- Components requiring light flexibility and dampening properties.

- Durable and impact resistant spare parts and robotics.

- Large scale functional prototyping.

PolyMide™ CoPA works best in relatively dry applications requiring strength and toughness. When first printed and annealed PolyMide™ CoPA will be in its dry state and overtime will absorb moisture from the air which boosts the flexibility and toughness of the material. It is generally assumed that any parts manufactured in Nylon 6 or Nylon 6,6 will reach their moisture conditioned state.

Most brands of Nylon filament can be very difficult to print, significantly warping and requiring specialty print surfaces to print.... but with Polymakers Warp-free™ technology, PolyMide™ CoPA is recognised as one of the easiest if not the most user friendly Nylon 6 based filaments on the market while still exhibiting excellent mechanical performance without compromise. PolyMide™ CoPA is well suited for mechanically demanding projects which to print in other engineering materials would require an industrial 3D printer.

One of the best examples of PolyMide™ CoPA's superior dimensional stability is Tongji Universities 3d printed Eco-Car.

By 3D printing using PolyMide™ CoPA, Tongji Universities ZEAL team could design and print the shell of their car to reduce air resistance and control the weight with different infil. 3D printing projects at this scale with other engineering grade materials like ABS, ASA, PC or other Nylon brands can be difficult without expensive industrial 3D printers.

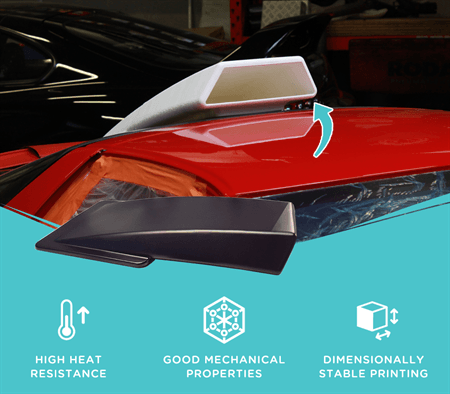

PolyMide™ CoPA has also been a chosen material for many other automotive manufacturers and repair shops. Custom Import Arts are a sports car tuning company taking advantage of these properties by printing custom fixtures and intakes that withstand the high heat and pressures involved in and around the engine. This air intake for a custom race modified Honda NSX is printed in 6 parts on a mid range desktop 3D printer, assembled, sanded and painted. The roof mounted intake delivers high volumes of air into the rear engined sports car

Custom Air Intake for race modified Honda NSX. Printed in PolyMide™ CoPA and post processed.

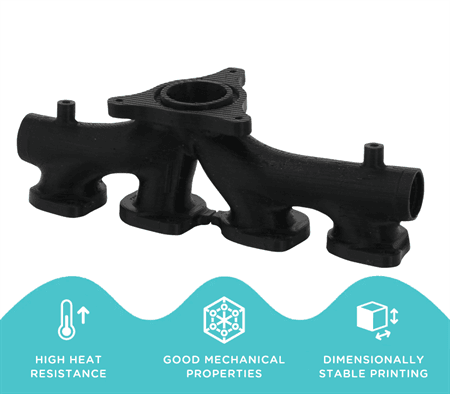

Automotive AC 3D printed in PolyMide™ CoPA natural colour.

PolyMide™ CoPA offers excellent resistance to oils and greases and after annealing, parts printed in PolyMide™ CoPA can handle high temperatures up to 180°C.

PolyMide™ CoPA is a long-wearing plastic, excellent for applications requiring durability or a low co-efficient of friction like gears, rollers and more!

PolyMide™ CoPA prints with excellent inter-layer adhesion and users with a dual extrusion 3D printer can print with Polymakers PolyDissolve™ S1, a dedicated support material engineered to deliver water dissolvable supports with perfect interfacing and improved part surface quality.

Printing Settings

| Nozzle Temperature | 250°C - 270°C |

|---|---|

| Build Plate Temperature | 25°C - 50°C* *Do not exceed 50°C! |

| Build Surface Material | Compatible with most common build surfaces. Apply a thin layer of glue stick to the build plate. |

| Build Surface Treatment | PVA or PVP glue stick. |

| Cooling Fan | OFF |

| Printing Speed | 30 mm/s - 60 mm/s |

| Retraction | The ideal retraction settings vary from printer to printer and depend on the hot end. The following settings have been a good starting point for many machines. Direct Drive: Retraction distance of 3mm with retraction speed of 50mm/s Bowden: Retraction distance of 6mm with retraction speed of 60mm/s |

| Enclosure | Not required but useful to protect from drafts and maintain a stable printing environment. |

| Heated Chamber | Not recommended. |

| Recommended Support Material | Single Extrusion: Self Support If PolyMide™ CoPA is used as the support material for itself, please remove the support structure before excessive moisture absorption. Otherwise the support structure can be permanently bonded to the model. Dual Extrusion: PolyDissolve™ S1 (Dissolve in tap water) Water soluble supports aren't recommended for parts requiring strict dimensional tolerance as nylon based filaments like CoPA will absorb water when dissolving soluble supports. |

Based on 0.4 mm nozzle. Printing conditions may vary with different printers and nozzle diameters.

Unlike other Nylon filaments which are notorious for warping, PolyMide™ CoPA has been formulated to print easily without a heated build plate or enclosure. Additional heat is not beneficial to the printing process so if you are using an industrial 3D printer we highly recommend turning off the heated chamber and not exceeding 50°C build plate temperature.

The primary consideration when printing Nylon is protection from moisture. See "Storage and Drying" details below for instructions to protect PolyMide™ CoPA. If printing large quantities of PolyMide™ CoPA it can be beneficial to switch to a wear resistant nozzle such as hardened steel nozzle since nylon can be more abrasive than PLA when used extensively.

Annealing Nylon CoPA

For the best mechanical performance it is recommended to anneal parts printed in PolyMide™ CoPA. Annealing is the process of heating up the printed parts at a certain temperature for a certain period of time. PolyMide™ CoPA displays outstanding mechanical and thermal properties when fully crystallised. The printed part will not reach full crystallisation after the printing process and annealing shortly after the printing process is required to complete this step.

Annealing Settings - 80˚C for 6 hours.

Specification

| Net Weight | 750g |

|---|---|

| Material Type | Copolymer of Nylon 6 and Nylon 6,6 |

| Density | 1.12 g/cm3 |

| Colour | Black |

Compatibility

PolyMide™ CoPA has been engineered so users can print tough Nylon parts with superior flatness and reliability, this is achieved through Polymakers warp-free™ technology which controls the crystallinity behaviour of the material.

Unlike other engineering materials like ABS and PC which benefit from a high temperature environment, it is important not to exceed the recommended build plate temperature when printing PolyMide™ CoPA.

PolyMide™ CoPA like other nylon filaments is very hygroscopic. This means that it is susceptible to absorbing moisture from the atmosphere which can subsequently affect the quality and mechanical properties of the final prints. See "Storage and Drying" details below for instructions to protect PolyMide™ CoPA.

Of course with thousands of unique 3d printer models on the market, we can't guarantee each filament type will work with every 3D printer.

Technical Data

All testing specimens were printed under the following conditions: Nozzle Temperature = 265˚C, build plate temperature = 50˚C, infil = 100%, cooling fan = OFF, build plate temperature = 40 - 60˚C

THERMAL PROPERTIES

All specimens were annealed prior to testing.

| Value | Testing Method | |

| Glass Transition | 67˚C | DSC, 10°C/min |

| Heat Deflection Temperature |

0.45 MPA - 110.5˚C |

ISO 75 0.45MPa |

| Vicat Softening Temperature | 180˚C | ISO 306, GB/T 1633 |

MECHANICAL PROPERTIES (DRY STATE)

All Dry State specimens were annealed and dried for 48h prior to testing.

| Value | Testing Method | |

| Youngs Modulus (X-Y) |

2223 ± 199 MPa | ISO 527, GB/T 1040 |

| Tensile Strength (X-Y) |

66.2 ± 0.9 MPa | ISO 527, GB/T 1040 |

| Elongation at break (X-Y) | 9.9 ± 1.5 % | ISO 527, GB/T 1040 |

| Bending Modulus (x-Y) | 1667 ± 118 MPa | ISO 178, GB/T 9341 |

| Bending Strength (X-Y) |

97 ± 1.1 MPa | ISO 178, GB/T 9341 |

| Charpy Impact Strength (X-Y) |

9.6 ± 1.4 kJ/m2 | ISO 179, GB/T 9343 |

MECHANICAL PROPERTIES (MOISTURE CONDITIONED)

All Moisture Conditioned specimens were annealed and conditioned at 70% relative humidity and ambient temperature for 15 days prior to testing.

| Value | Testing Method | |

| Youngs Modulus (X-Y) |

1053 ± 235 MPa | ISO 527, GB/T 1040 |

| Tensile Strength (X-Y) |

31.4 ± 1.5 MPa | ISO 527, GB/T 1040 |

| Elongation at break (X-Y) | 215.5 ± 12.1 % | ISO 527, GB/T 1040 |

| Bending Modulus (x-Y) | 862.8 ± 133.3 MPa | ISO 178, GB/T 9341 |

| Bending Strength (X-Y) |

41.6 ± 11.6 MPa | ISO 178, GB/T 9341 |

| Charpy Impact Strength (X-Y) |

17.2 ± 1.4 kJ/m2 | ISO 179, GB/T 9343 |

We have full MDS and technical data sheets for PolyMide™ CoPA and all other Polymaker products. Contact us to enquire!

The typical values presented in Polymakers data sheet are intended for reference and comparison purposes only. Due to the nature of 3D printing they should not be used for design specifications or quality control purposes.

STORAGE & DRYING

Nylon filaments are very hygroscopic meaning they quickly absorb moisture from the air which can affect printing quality and strength of printed parts. Before packaging, PolyMide™ CoPA is dried to ensure the best printing quality and filaments are vacuum sealed in a resealable mylar bag to protect the filament from moisture.

- When opening, carefully open the resealable bag, remove the spool and close the bag back to preserve the desiccant bag.

- Print PolyMide CoPA from a dry box with a 10 - 15% RH which will protect the filament from absorbing moisture. We recommend Polymaker PolyBox™ which uses desiccant to keep the filament at dry conditions (relative humidity of 15% or less) without using heat. Dry boxes with a heating element can degrade plastic filaments if used extensively.

- After the print is completed, PolyMide™ CoPA can be stored in the PolyBox™, be sure to monitor and maintain the desiccant to keep RH below 15% RH. If a PolyBox™ is not being used the filament can be resealed in the resealable bag at the end of the print. In both situations it's recommended to store the filament away from sunlight for long term storage and replace / dry the desiccant as required.

These recommendations are ultimately to prevent the filament from absorbing moisture in the first place. If you hear popping sounds and notice that the surface quality of your print is uneven or the colour is not consistent, this is a likely indicator that the filament has absorbed too much moisture and can be remedied. Spools of PolyMide™ CoPA can be dried in a preheated convection oven at 80˚C for up to 12 hours.

Although drying is a suitable solution it's highly recommended not to excessively dry the filament and instead take precautions to prevent moisture absorption. Continually drying any plastic can make it more brittle and moisture content can also cause filaments to become more brittle due to hydrolysis.

FAQ

Q: What is the "Dry" state vs "Wet" state?

A: Nylon 6 / 6,6 materials absorb moisture not only as a filament but also the final printed part, we call this process moisture conditioning. The "Dry" state is the printed part immediately after annealing and the "Wet" state represents the mechanical properties after absorbing moisture from the air, there is a third state "Saturated" which represents the properties if the material is submerged in water. As the printed part absorbs moisture, it will become more flexible and impact resistant, seeing a decrease in rigidity and tensile strength when compared to its dry state. It is generally assumed that for most users, their PolyMide™ CoPA 3D prints will eventually reach their "Wet" state however there are numerous cases where the part may never become moisture conditioned. Examples include components operating in a high temperature environment, 3D prints that have been post-processed and protected with a moisture barrier or perhaps for applications where the PolyMide™ CoPA is submerged in a specific chemical or oil.

Q: How well does Polymakers Warp-Free™ technology perform?

A: With Polymakers Warp-Free technology, more users can effectively print CoPA with better dimensional stability than comparative nylon products. This technology works best when printing with low bed/chamber temperatures. Because the warping behaviour of Nylon materials is partially related to its crystallisation rate while printing. If a user does print with a high temperature heated bed or chamber, the heat will increase the crystallisation rate and cause a part to warp.

Q: Is annealing PolyMide™ CoPA required?

A: After printing, annealing PolyMide™ CoPA prints will ensure the highest degree of crystallinity. This is a recommended step as it allows end users to get the best properties and performance from their parts. PolyMide™ CoPA can be annealed in a convection oven at 80˚C for 6 hours. Of course annealing may not be required for applications that don't require the best thermal or mechanical properties. In some rare cases with fine or thin geometries, different annealing instructions or design considerations may be required for the best results.

Q: Does PolyMide™ CoPA distort during the annealing process?

A: After

Q: Will this filament absorb moisture?

A: Yes, Polyamides are hygroscopic, meaning that they absorb moisture from the air. We recommend keeping your spool of PolyMide™ CoPA dry as moisture can significantly reduce mechanical properties and cause print defects such as oozing and poor surface quality. To manage moisture absorption in your filaments, it is recommended to use the PolyBox™ which provides a stable, low level humidity storage solution for filaments during and in-between printing. If PolyMide™ CoPA appears to have absorbed too much moisture, they can be dried in a preheated convection oven for 12 hours at 80˚C.

Q: Is PolyMide™ CoPA suitable for high humidity or "wet" applications?

A: Unless post-processed with a moisture barrier, it is generally not recommended to use Nylon 6 / 6,6 based filaments in a water based application. Printed parts can become completely saturated if submerged which will soften the part and cause distortion. For these applications it is recommended to use an alternative polymer or consider a longer chain nylon such as PA12. PA12 absorbs significantly less moisture than PA6 which ultimately offers are more stable material for high humidity and wet applications.

Q: What support materials can I use with this product?

A: It is recommended to print self supports and remove the support structures straight after printing, as prolonged exposure to atmospheric humidity can cause the support to strongly adhere to the printed part. If your printer is equipped for multi-material printing, Polymaker’s PolyDissolve™ S1 (PVA) will adhere well to PolyMide™ CoPA however there are some downsides to using water soluble supports with Nylon 6, especially if dimensional accuracy is important.

Q: Should I rewind this filament if I want to use it with a different spool?

A: We strongly advise against tampering with the product by rewinding. See our article for full details about the risks. All Polymaker filaments are wound with tension but without strain. Rewinding completely rearranges the curvature of the winding and this strain over time can cause most plastics to catastrophically break. If for some reason your printer is locked into fitting less than standard sized spools, there may be safe printable adaptors or external mounting solutions available.

Don't know where to start? Or which filament will suit your application? We have a broad range of support options including telephone support. Contact us today!

• Orders ship out of Townsville, QLD, Australia at 1530.

• Active on Instagram - Tag us or DM us!

• Watch what we are up to on our YouTube Channel!

• Join our Facebook Page for updates and RSFPV news.

• GST Registered.

• Gifts with every order!

• Veteran Owned and Operated

• Defence and Service discounts - Apply Here

• 3D Printing and Custom design – Inquire Here.

• Visit us at our Store and have a yarn.

• Sponsor of Townsville FPVR, Next Level FPV

and the Australian Army Drone Racing Team.

• FPV Drone service, support and repairs.

• Earn points for every $1 spent.

• Buy now and pay later with Zippay, Afterpay, Humm and Laybuy.