Dedicated easy break away support material for Polymaker PA12 and PA612 filaments.

- Dedicated break-away support material for long-chain nylon.

- Low moisture sensitivity compared to soluble support materials.

- Can improve interface surface quality.

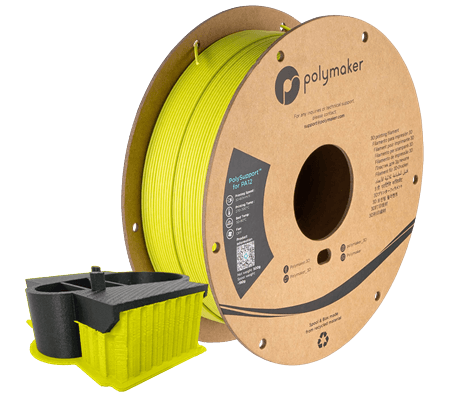

- Bright green colour to easily distinguish support.

- Cardboard spool & packaging (made from 100% recycled cardboard)

PolySupport™ for PA12 is a break away support for Polymaker PA12, PA612 and other long-chain nylon based filaments. It has a perfect interface with PA12 and other long-chain nylon based material, strong enough to support it and easily removable by hand.

Features

-

Peel Away - PolySupport™ for PA12 is a breakaway support material designed for easy mechanical removal from printed models. Compared to dissolvable support, PolySupport™ for PA12 can break away easily from the model and is ideal for 3D printing geometric models such as jigs and fixtures or covering parts since PolySupport™ for PA12 will be removed faster and more easily than a dissolvable support.

-

Designed for Long-Chain Nylon - PolySupport™ for PA12 has been specially engineered to provide a perfect interface with Polymaker's long-chain nylons, such as PolyMide™ PA12-CF and PA612-CF. Its superior adhesion properties create a reliable bond between the support and the model, ensuring optimal print quality yet reliable support removal. The bright green colour makes it easy to distinguish between the model and support structure during the removal process.

-

Low Moisture Sensitivity - PolySupport™ for PA12 is less sensitive to moisture compared to some dissolvable support materials, resulting in a more stable printing process. Unlike dissolvable supports, it requires no solvents, and you can immediately peel the supports away without waiting for them to dissolve, saving you time.

-

Improved surface quality - By using PolySupport™ for PA12, you can improve the surface quality where supports interface with your prints, resulting in smoother and more refined surfaces. Dedicated support materials can significantly reduce the visibility of support marks on your prints, creating a better overall print quality.

-

Uncompromised Quality - Polymakers leading quality control process and rigorous in-house testing ensure reliable printing and consistency across spools and batches

|

Filament |

| Diameter |

1.75mm |

| Spool Weight |

500g |

Printing Settings

| Nozzle Temperature |

270°C - 300°C |

| Build Plate Temperature |

50°C - 80°C |

| Build Surface Material |

Works well with most build surfaces with a thin layer of glue stick. |

| Enclosure |

See recommendations for the modelling material. |

| Heated Chamber |

See recommendations for the modelling material. |

| Cooling Fan |

Generally turn 'OFF' but refer to recommendations for the modelling material.

|

| Printing Speed |

30 mm/s - 60 mm/s |

| Retraction |

The ideal retraction settings vary from printer to printer and depend on the hot end. The following settings have been a good starting point for many machines.

Direct Drive: Retraction distance of 1mm with retraction speed of 20mm/s

Bowden: Retraction distance of 3mm with retraction speed of 40mm/s |

Based on 0.4 mm nozzle. Printing conditions may vary with different printers, higher speeds / flow rates and nozzle diameters.

Secondary support materials work best on printers with two nozzles, enabling you to use separate temperatures for the modelling material and support material.

Support Settings

It's recommended to check print-preview to see the effect of these settings and check if the result is desired. Based on 0.4 mm nozzle. Printing conditions may vary with different printers, higher speeds / flow rates and nozzle diameters.

This material has been formulated by Polymaker to offer compatibility with PolyMide PA12-CF and PolyMide PA612-CF.

Before we discuss the printing settings for PolySupport™ for PA12, it is important that we identify the two different types of support structures. Generally speaking, we classify support structures into two categories: open support and closed support.

Open support: Support that does not enclose any portion of the model. Open support can usually be removed in a single piece.

Closed support: Support that encloses some portion of the model. In this case the support must be broken apart and separated in order to be removed from the finished part.

Open Support

| Support Density |

Since open support can be removed in a single piece, we recommend a high support density (40% or more) with 2 layers of solid inter-face to obtain better surface finish.

|

| Support Interface |

A dense support interface between the model and the support can also be used to improve the surface quality of the supported face. We recommended 2 dense layers at 90% infill. Dense support interfaces are harder to remove than the less dense structures, so may not be ideal for all geometries. |

| Support Infil Pattern |

For open support, since the support structure can be removed relatively easily, perpendicular infill is generally recommended. |

| Threshold Overhang Angle |

Most 3D printers can print overhang angles up to 45˚ , so it is recommended that the threshold overhang angle be set at 45˚. |

| Support Horizontal Expansion |

Horizontal expansion extends support beyond the footprint. Up to 2mm can help expand the footprint of support, especially for tall support structures. |

| Support Vertical Gap / Support Z Distance |

This setting is generally a multiple of your layer height. With dedicated support materials you can set the distance to 0mm or 0 layers to ensure the PA12 filament is printing directly onto the solid support inter-face layer.

If your printer uses two or more nozzles, the result of this setting is assuming the two nozzles have been calibrated and are aligned vertically. |

Closed Support

| Support Density |

It is recommended that a support density in the range of 15% - 30% is used for closed support for easy removal.

|

| Support Interface |

A dense support interface between the model and the support can also be used to improve the surface quality of the supported face. We recommended 2 dense layers at 90% infill.

Dense support interfaces are harder to remove than the less dense structures especially in internal structures, so may not be ideal for all geometries. Interface can be held with pliers or cut. |

| Support Infil Pattern |

It is recommended that the infill always be parallel for closed support to better break it away |

| Threshold Overhang Angle |

Most 3D printers can print overhang angles up to 45˚ , similar with open support, a threshold overhang

angle of 45˚ is generally recommended. |

| Support Horizontal Expansion |

Horizontal expansion extends support beyond the footprint. Up to 2mm can help expand the footprint of support, especially for tall support structures. |

| Support Vertical Gap / Support Z Distance |

With dedicated support materials you can set the distance to 0mm or 0 layers to ensure the PA12 filament is printing directly onto the solid support inter-face layer.

If your printer uses two or more nozzles, the result of this setting is assuming the two nozzles have been calibrated and are aligned vertically.

If support is tricky and the nozzles are perfectly aligned, you can also purposefully print with a vertical gap, in the same way we print with single extrusion self supports. If printing with a 0.1mm layer height try a 0.1mm or 0.2mm support z distance, with 0.2mm layer height try a 0.2mm support z distance. |

For other tips printing PolySupport™ for PA12 contact us!

Compatibility

PolySupport™ for PA12 has been engineered to be compatible with Polymakers PA12 based filaments. This material requires a heated bed though the specific requirements depend on the modelling material you use. Compatibility with other brands / formulas has not necessarily been tested.

Performance and the quality of multi-material printing can greatly vary depending on your printer, technology, calibration of the multiple nozzles (if applicable) and inactive hot end temperature cool down settings. Of course with thousands of unique 3d printer models on the market, we can't guarantee each filament type will work with every 3D printer.

STORAGE & DRYING

Before packaging, PolySupport™ for PA12 is dried to ensure the best printing quality and filaments are vacuum sealed to protect the filament from moisture. When not in use PolySupport™ for PA12 should be stored away from sunlight in the packaged resealable bag.

Like other filaments, PolySupport™ for PA12 is susceptible to absorbing moisture from the air, just not to the same extent as soluble support filaments. We recommend storing PolySupport™ for PA12 in the PolyBox™ or a dry cabinet during printing to prevent moisture absorption which will lower the quality of the print. The PolyBox™ keeps the filament at dry conditions (relative humidity of 15% or less).

If you hear popping sounds and notice that the surface quality of your print is uneven or the color is not consistent, this is a likely indicator that the filament has absorbed too much moisture. Spools of PolySupport™ for PA12 can be dried in a preheated convection oven at 55˚C for up to 6 hours. Results may vary depending on the accuracy of your oven so please be conservative. For more information about filament drying please read our user guide.

Don't know where to start? Or which filament will suit your application? We have a broad range of support options including telephone support. Contact us today!